Abstract

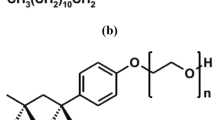

The strength of a newly formulated surfactant with an alkali and polymer (AS/ASP) to improve an acidic heavy oil recovery was laboratory evaluated by various flooding experiments. The comparative role of the parameters like chemical nature, surface wettability, salinity, temperature and injection scheme were explored at high temperature and pressure on Berea sandstone rocks. According to the results the anionic surfactant is capable of providing proper oil displacement under high salinity conditions around 15 wt%. Continuous monitoring of differential pressure response and effluents’ state clearly represented the formation of an emulsified oil in high saline solutions with both alkali and surfactant. Adding sodium metaborate to the surfactant solution reduced the interfacial tension (IFT) to ultra low values and decreased the surfactant emulsion generation capability at higher salinities. Besides, adding Flopaam AN113SH to the chemical slug increased the residual oil removal owing to lower mobility ratios. So, while high capillary number and an emulsion phase were generated by the A/S slug phases, adding polymer could further enhance the performance of these chemicals. On the other hand, chemical flooding through the oil-wet medium resulted in shorter break through time, lower differential pressure, finer emulsion formation, and lower oil recovery in comparison to the similar water-wet cases.

Similar content being viewed by others

References

Healy RN, Reed RL. Physicochemical aspects of microemulsion flooding. SPEJ, SPE-4583 1974;14(5):491–501. doi:10.2118/4583-PA.

Hirasaki GJ, Zhang DL. Surface chemistry of oil recovery from fractured, oil-wet, carbonate formations. SPEJ, SPE-88365 2003;9(2):151–62. doi:10.2118/88365-PA.

Adibhatla B, Mohanty KK. Oil recovery from fractured carbonates by surfactant-aided gravity drainage: laboratory experiments and mechanistic simulations. SPE-99773-PA 2008;11(1):119–30. doi:10.2118/99773-PA.

Arihara N, Yoneyama T, Akita Y, Lu X. Oil recovery mechanisms of alkali–surfactant–polymer flooding. In: SPE-54330-MS, SPE Asia Pacific oil and gas conference and exhibition, Indonesia. 1999. doi:10.2118/54330-MS.

Krumrine PH, Falcone JS, Campbell TC. Surfactant flooding 1: the effect of alkaline additives on IFT, surfactant adsorption, and recovery efficiency. SPEJ, SPE-8998. 1982;22(4):503–13. doi:10.2118/8998-PA.

Shuler PJ, Kuehne DL, Lerner RM. Improving chemical flood efficiency with micellar/alkaline/polymer processes. JPT, SPE-14934 1989;41(1):80–8. doi:10.2118/14934-PA.

Martin FD, Oxley JC, Lim H. Enhanced recovery of a “J” sand crude oil with a combination of surfactant and alkaline chemicals. In: SPE 14293, SPE annual technical conference and exhibition, Nevada. 1985. doi:10.2118/14293-MS.

Olsen DK, Hicks MD, Hurd BG, Sinnokrot AA, Sweigart CN. Design of a novel flooding system for an oil-wet Central Texas carbonate reservoir. In: SPE 20224, SPE/DOE enhanced oil recovery symposium, Oklahoma. 1990. doi:10.2118/20224-MS.

French TR, Burchfield TE. Design and optimization of alkaline flooding formulations. In: SPE-20238, SPE/DOE enhanced oil recovery symposium, Oklahoma. 1990. doi:10.2118/20238-MS.

Zhang DL, Liu S, Puerto M, Miller CA, Hirasaki J. Wettability alteration and spontaneous imbibition in oil-wet carbonate formations. J Petrol Sci Eng. 2006;52(1–4):213–26.

Seethepalli A, Adibhatla B, Mohanty KK. Wettability alteration during surfactant flooding of carbonate reservoirs. In: SPE 89423, SPE/DOE symposium on improved oil recovery, Oklahoma. 2004. doi:10.2118/89423-MS.

Cooke Jr CE, William RE, Kolodzie PA. Oil recovery by alkaline waterflooding. J Pet Tech SPE-4739 1974;26(12):1365–74. doi:10.2118/4739-PA.

Ehrlich R, Wygal RJ. Interrelation of crude oil and rock properties with the recovery of oil by caustic water flooding. In: SPEJ, SPE-5830, vol. 17(4), pp. 263–70;1977. doi:10.2118/5830-PA.

Xie J, Chung B, Leung L. Design and implementation of a caustic flooding EOR pilot at Court Bakekken heavy oil reservoir. In: SPE-117221, international thermal operations and heavy oil symposium, Canada. 2008. doi:10.2118/117221-MS.

Rudin J, Wasan DT. Mechanisms for lowering of interfacial tension in alkali/acidic oil systems: effect of added surfactant. Ind Eng Chem Res. 1992;31(8):1899–906. doi:10.1021/ie00008a010.

Liu Q, Dong M, Ma S, Tu Y. Surfactant enhanced alkaline flooding for Western Canadian heavy oil recovery. Colloids Surf A. 2007;293(1):63–71. doi:10.1016/j.colsurfa.2006.07.013.

Dong M, Ma S, Liu Q. Enhanced heavy oil recovery through interfacial instability: a study of chemical flooding for Brintnell heavy oil. Fuel. 2009;88(6):1049–56. doi:10.1016/j.fuel.2008.11.014.

Pitts MJ, Dowling P, Wyatt K, Sukarlo H, Adams C. Alkaline–surfactant–polymer flood of the Tanner field. In: SPE 100004, SPE/DOE symposium on improved oil recovery, Oklahoma. 2006. doi:10.2118/100004-MS.

Pratap M, Gauma MS. Field implementation of alkaline–surfactant–polymer (ASP) flooding: a maiden effort in India. In: SPE 88455, SPE Asia Pacific oil and gas conference and exhibition, Australia. 2004. doi:10.2118/88455-MS.

Li H, Liao G, Han P, Yang Z, Wu X, Chen G, Xu D, Jin P. Alkaline/surfactant/polymer (ASP) commercial flooding test in central Xing2 area of Daqing oilfield. In: SPE 84896, SPE international improved oil recovery conference in Asia Pacific, Malaysia. 2003. doi:10.2118/84896-MS.

Chang HL, Zhang ZQ, Wang QM, Xu ZS, Guo ZD, Sun HQ, Cao XL, Qiao Q. Advances in polymer flooding and alkaline/surfactant/polymer processes as developed and applied in the People’s Republic of China. JPT, SPE-89175 2006;58(2):84–89. doi:10.2118/89175-JPT.

Pei H, Zhang G, Ge J, Tang M, Zheng Y. Comparative effectiveness of alkaline flooding and alkaline–surfactant flooding for improved heavy-oil recovery. Energy Fuels. 2012;26(5):2911–9. doi:10.1021/ef300206u.

Dehghan AA, Masihi M, Ayatollahi Sh. Evaluation of chemicals interaction with heavy crude oil through water/oil emulsion and interfacial tension study. Energy Fuels. 2013;27(10):5852–60. doi:10.1021/ef401361t.

Dehghan AA, Jadaly A, Masihi M, Ayatollahi Sh. Studying the mechanistic behavior of heavy oil displacement using a group of alkalis and surfactant mixtures. Chem Eng Commun. 2015;202(3):366–74. doi:10.1080/00986445.2013.83.

Acknowledgements

The authors would like to acknowledge the financial support of the Iranian Offshore Oil Company (Research and Technology Department) for performing the experiments and the permission to publish the results.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Dehghan, A.A., Jadaly, A., Ayatollahi, S. et al. Acidic Heavy Oil Recovery Using a New Formulated Surfactant Accompanying Alkali–Polymer in High Salinity Brines. J Surfact Deterg 20, 725–733 (2017). https://doi.org/10.1007/s11743-017-1945-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11743-017-1945-9